1. Introduction

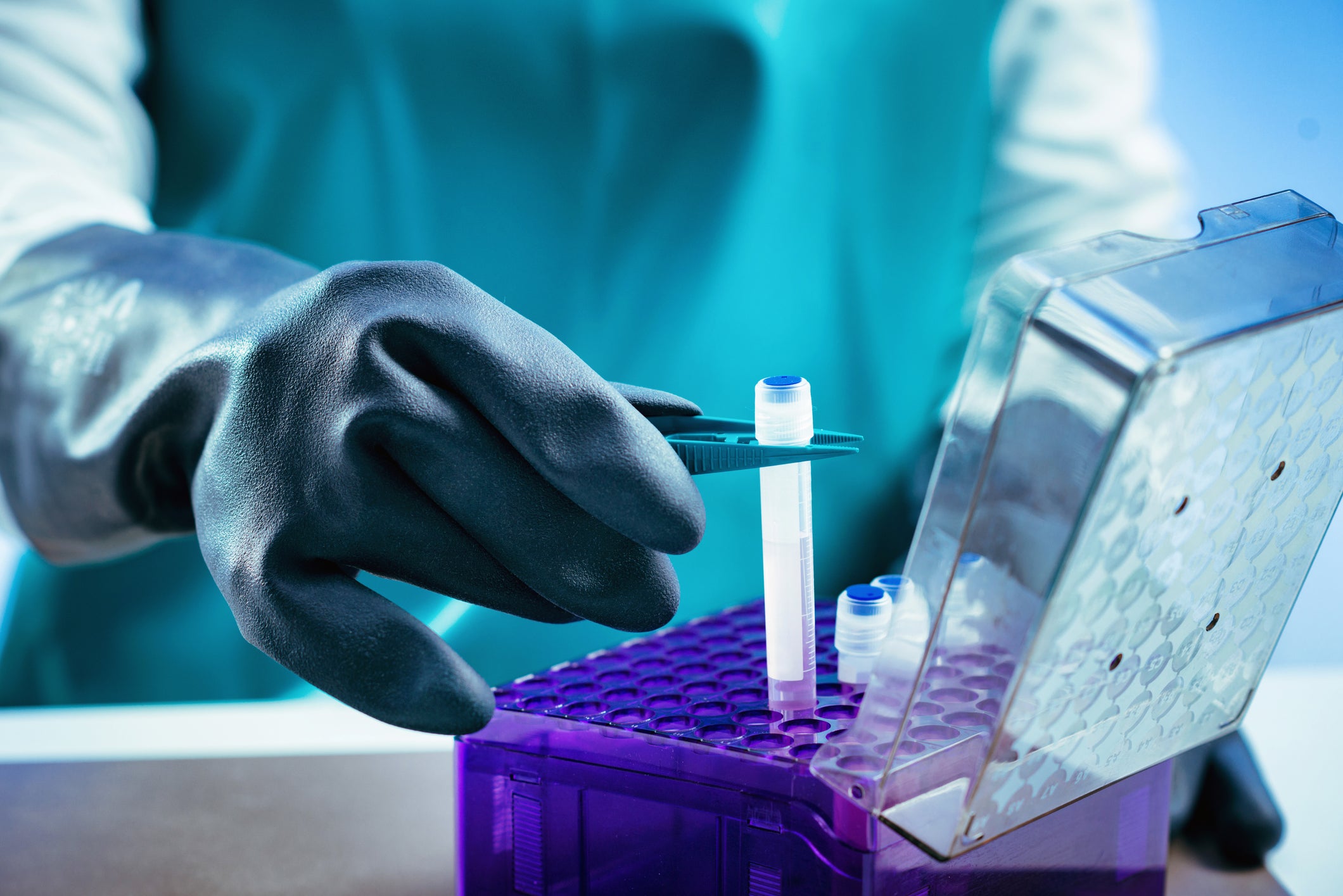

Cryogenic gloves stand as the unsung heroes in environments where temperatures plummet to chilling extremes. They shield hands from the bone-chilling cold, ensuring safety and comfort for those working in cryogenic environments. In this article, we delve into the intricacies of cryogenic gloves, exploring their features, functionality, and why they're indispensable in various industries.

2. What are Cryogenic Gloves?

Cryogenic gloves are specialized hand protection gear designed to withstand ultra-low temperatures typically encountered in cryogenic environments. Crafted from advanced materials, these gloves act as a barrier between the skin and extreme cold, providing insulation to prevent frostbite and other cold-related injuries.

3. How do Cryogenic Gloves Work?

These gloves employ multiple layers of insulating materials such as neoprene, leather, and specialized fabrics. These layers work synergistically to create a thermal barrier, effectively trapping body heat and preventing external cold from penetrating. Additionally, some gloves feature enhanced grip surfaces to ensure dexterity and control even in icy conditions.

4. Types of Cryogenic Gloves

There are various types of cryogenic gloves tailored to specific applications and temperature ranges. Common types include:

-

Multi-layered Insulated Gloves: Suitable for moderate to extremely low temperatures, these gloves offer robust protection and flexibility.

-

Waterproof Cryogenic Gloves: Ideal for environments with moisture exposure, these gloves repel water while maintaining insulation properties.

-

Extended Cuff Gloves: Providing additional protection to the wrist and forearm, these gloves are essential for tasks requiring immersion in cryogenic liquids.

5. Features to Consider

When selecting cryogenic gloves, several factors should be considered:

-

Temperature Resistance: Ensure the gloves can withstand the intended temperature range without compromising protection.

-

Flexibility and Dexterity: Opt for gloves that allow for unhindered movement and tactile sensitivity.

-

Durability: Choose gloves crafted from high-quality materials to withstand frequent use and harsh conditions.

-

Comfort: Prioritize gloves with soft inner linings and ergonomic designs to enhance comfort during prolonged wear.

6. Benefits of Cryogenic Gloves

The utilization of cryogenic gloves offers numerous benefits:

-

Protection: Guards against frostbite, cold burns, and other cold-related injuries, ensuring the safety of workers.

-

Comfort: Maintains hand warmth and flexibility, allowing for prolonged work in extreme conditions.

-

Enhanced Grip: Some gloves feature textured surfaces for improved grip, enabling precise handling of equipment and materials.

7. Applications

Cryogenic gloves find extensive applications across various industries:

-

Medical and Healthcare: Used in cryosurgery, laboratory research involving cryogenic substances, and handling of frozen biological samples.

-

Industrial: Essential for workers in liquefied natural gas (LNG) plants, liquid nitrogen storage facilities, and cryogenic material handling.

8. Safety Precautions

While cryogenic gloves provide excellent protection, it's vital to observe safety precautions:

-

Proper Ventilation: Ensure adequate ventilation in enclosed spaces to prevent buildup of cryogenic gases.

-

Training: Provide comprehensive training on the proper use of cryogenic gloves and handling of cryogenic materials.

-

Regular Inspections: Periodically inspect gloves for signs of wear or damage, and replace them as needed to maintain optimal protection.

9. Maintenance and Care

To prolong the lifespan of cryogenic gloves:

-

Cleanliness: Regularly clean gloves with mild detergent and water to remove dirt and contaminants.

-

Storage: Store gloves in a cool, dry place away from direct sunlight and sources of heat.

-

Avoiding Chemical Exposure: Keep gloves away from corrosive chemicals or substances that may degrade the material.

10. Choosing the Right Size

Selecting the correct size of cryogenic gloves is crucial for optimal performance and comfort. Gloves that are too loose may compromise dexterity, while those that are too tight can restrict blood flow and cause discomfort. Refer to manufacturer sizing charts and consider trying on different sizes to find the perfect fit.

11. Common FAQs

Q1: Can cryogenic gloves protect against contact with cryogenic liquids?

Yes, cryogenic gloves are designed to provide protection against exposure to cryogenic liquids, but it's essential to use gloves specifically rated for liquid contact and follow proper safety protocols.

Q2: Are cryogenic gloves suitable for use in food handling applications?

While some cryogenic gloves may be suitable for food handling, it's crucial to verify that the gloves meet relevant safety standards and regulations for contact with food substances.

Q3: Can cryogenic gloves be used in conjunction with other personal protective equipment (PPE)?

Yes, cryogenic gloves can be worn alongside other PPE such as safety goggles, face shields, and insulated clothing to provide comprehensive protection in cryogenic environments.

Q4: How often should cryogenic gloves be replaced?

The frequency of glove replacement depends on factors such as usage intensity, exposure to harsh conditions, and signs of wear or damage. Inspect gloves regularly and replace them as needed to ensure continued protection.

Q5: Can cryogenic gloves be used in outdoor environments?

Yes, many cryogenic gloves are suitable for outdoor use, but it's essential to choose gloves with appropriate insulation and weather-resistant properties for outdoor applications.

12. Conclusion

Cryogenic gloves play a vital role in safeguarding hands from the extreme cold encountered in cryogenic environments. With their advanced insulation properties and ergonomic designs, these gloves ensure both safety and comfort for workers across various industries. By understanding the features, applications, and proper maintenance of cryogenic gloves, individuals can mitigate risks and maximize productivity in cold working conditions.