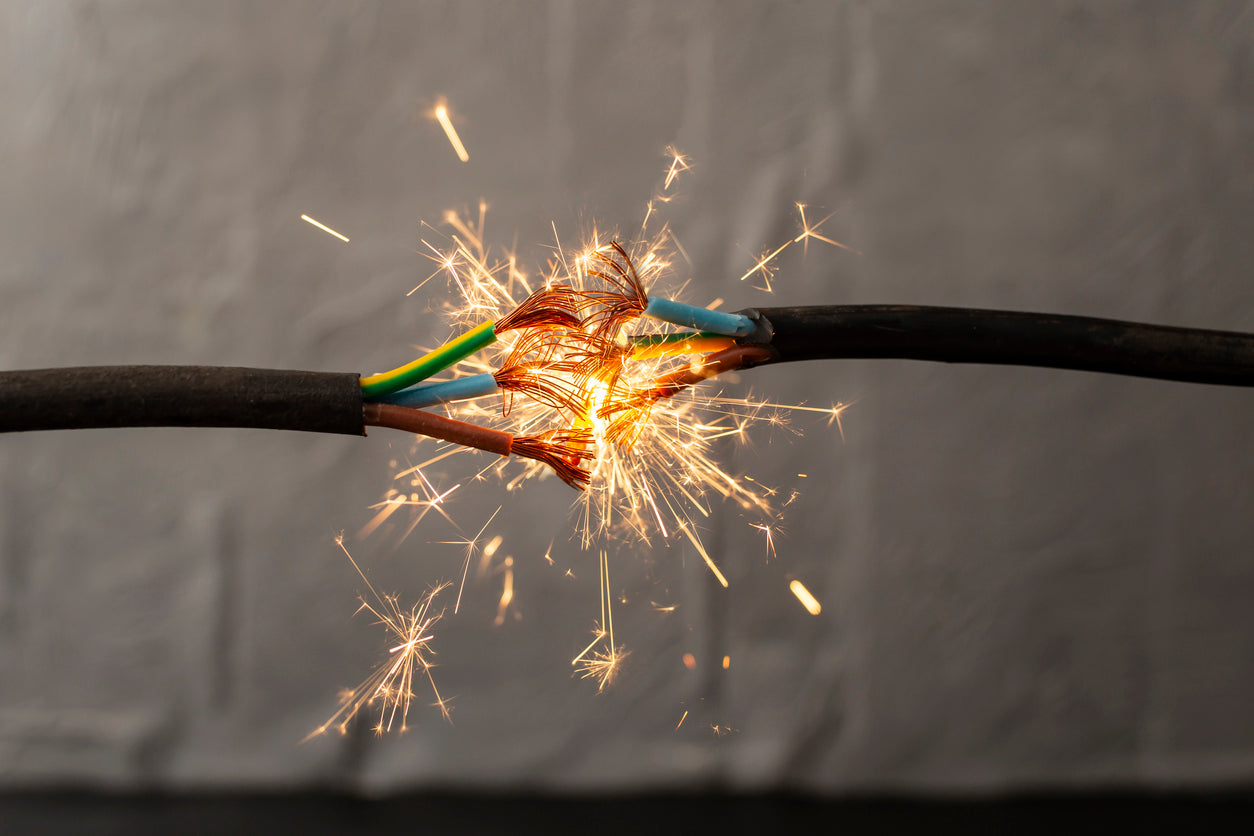

Electrical hazards pose significant risks to workers across various industries, from manufacturing plants to construction sites and office environments. NFPA 70E, titled "Standard for Electrical Safety in the Workplace," provides comprehensive guidelines to mitigate these risks and ensure the safety of personnel working on or near electrical equipment. This article explores the key aspects of NFPA 70E, its importance in promoting electrical safety, and practical applications for workplaces.

What is NFPA 70E?

NFPA 70E is a standard published by the National Fire Protection Association (NFPA), a leading organization in the field of fire safety and electrical safety standards. Originally developed in response to OSHA (Occupational Safety and Health Administration) regulations, NFPA 70E outlines safety practices and procedures to protect workers from electrical hazards associated with the use of electricity for tasks such as installation, operation, maintenance, and repair of electrical systems and equipment.

Key Components of NFPA 70E:

-

Scope and Purpose: NFPA 70E focuses on safeguarding employees from electrical hazards by providing requirements for establishing a safe work environment. It addresses electrical safety principles, risk assessment, protective measures, and training.

-

Hazard Identification and Risk Assessment: One of the fundamental aspects of NFPA 70E is the requirement for employers to conduct a thorough electrical hazard risk assessment. This involves identifying potential hazards associated with electrical equipment, systems, and tasks performed by employees.

-

Safety Procedures and Practices: The standard emphasizes the importance of implementing safety procedures and practices to minimize the risk of electrical accidents. This includes de-energizing electrical equipment before work begins whenever possible, using lockout/tagout procedures to control hazardous energy, and establishing safe work practices for tasks performed near energized equipment.

-

Personal Protective Equipment (PPE): NFPA 70E specifies the types of PPE that should be used to protect workers from electrical hazards, such as arc flash and shock. This includes arc-rated clothing, face shields, gloves, and other protective gear designed to reduce the severity of injuries in case of an incident.

-

Training Requirements: The standard mandates that employers provide training to employees who may be exposed to electrical hazards as part of their job duties. Training topics include electrical safety principles, hazard recognition, safe work practices, emergency procedures, and the proper use of PPE.

-

Arc Flash and Arc Blast Hazards: NFPA 70E addresses the risks associated with arc flash and arc blast events, which can occur during electrical faults or equipment failures. It provides guidelines for assessing the arc flash hazard, determining safe working distances, and implementing protective measures to mitigate the effects of these hazards.

-

Compliance and Implementation: While NFPA 70E itself is not a federal regulation, compliance with its requirements is often considered best practice and may be enforced through state or local regulations, industry standards, or as part of contractual obligations with clients or stakeholders.

Practical Applications in the Workplace

Implementing NFPA 70E in the workplace involves several practical steps aimed at ensuring the safety of employees working with or near electrical equipment. Here’s how NFPA 70E is applied in various workplace settings:

1. Electrical Safety Program Development

Employers are encouraged to develop and implement an electrical safety program based on the guidelines outlined in NFPA 70E. This includes:

-

Policy and Procedures: Establishing written policies and procedures that outline the organization’s commitment to electrical safety, including hazard identification, risk assessment methods, and control measures.

-

Safety Audits and Inspections: Conducting regular safety audits and inspections to assess compliance with NFPA 70E requirements, identify potential hazards, and address any deficiencies in electrical safety practices.

-

Documentation: Maintaining records of electrical safety training, hazard assessments, equipment maintenance, and incident investigations to demonstrate compliance with safety standards and regulatory requirements.

2. Electrical Hazard Risk Assessment

Before performing any work involving electrical equipment, employers must conduct a thorough electrical hazard risk assessment. This process includes:

-

Identification of Hazards: Identifying potential electrical hazards such as exposed energized conductors, faulty equipment, inadequate insulation, and improper grounding.

-

Risk Evaluation: Assessing the severity and likelihood of injury or damage that could result from identified hazards, considering factors such as voltage levels, equipment condition, and task complexity.

-

Hierarchy of Controls: Implementing controls to mitigate identified hazards, following the hierarchy of controls that prioritize elimination, substitution, engineering controls, administrative controls, and PPE.

3. Electrical Work Permit System

NFPA 70E recommends implementing an electrical work permit system for tasks involving energized electrical equipment or systems. The work permit system helps ensure that proper safety precautions are followed before, during, and after performing electrical work. Key components of the electrical work permit system include:

-

Approval Process: Obtaining authorization from designated personnel (e.g., supervisors, safety officers) before starting work on energized electrical equipment.

-

Safety Precautions: Identifying and implementing necessary safety precautions, including equipment de-energization, lockout/tagout procedures, and PPE requirements based on the hazard assessment.

-

Job Briefings: Conducting pre-job briefings with workers involved in electrical work to review safety procedures, communicate potential hazards, and discuss emergency response procedures.

4. Training and Qualifications

Training plays a critical role in ensuring that employees have the knowledge and skills to work safely around electrical hazards. NFPA 70E requires employers to provide training that covers:

-

Electrical Safety Principles: Educating employees on the fundamentals of electrical safety, including the nature of electrical hazards, shock hazards, arc flash hazards, and arc blast hazards.

-

Safe Work Practices: Instructing employees on safe work practices for tasks such as testing, troubleshooting, voltage testing, and using electrical tools and equipment.

-

Emergency Response Procedures: Training employees on emergency response procedures, including how to respond to electrical shock incidents, arc flash incidents, and other electrical emergencies.

-

PPE Selection and Use: Providing guidance on selecting, inspecting, and properly using PPE, such as arc-rated clothing, gloves, face shields, and hearing protection.

5. Arc Flash Hazard Analysis and Labeling

NFPA 70E requires employers to conduct an arc flash hazard analysis to assess the potential for arc flash incidents and determine the appropriate safety precautions. This includes:

-

Arc Flash Boundary: Establishing the arc flash boundary, which is the distance from an arc source within which a person could receive a second-degree burn if an arc flash were to occur.

-

PPE Categories: Identifying the arc flash PPE categories based on the incident energy level at various working distances, as determined by the arc flash hazard analysis.

-

Arc Flash Labels: Affixing arc flash warning labels to electrical equipment that indicates the potential hazard and specifies the required PPE category and other safety precautions.

6. Equipment Maintenance and Testing

Regular maintenance and testing of electrical equipment are essential to ensure its safe operation and compliance with NFPA 70E requirements. This includes:

-

Inspection and Testing: Conducting routine inspections and electrical testing of equipment to identify defects, damage, or deterioration that could pose electrical hazards.

-

Preventive Maintenance: Implementing a preventive maintenance program to address equipment deficiencies, replace worn components, and ensure that electrical systems remain in a safe operating condition.

-

Equipment Labeling: Properly labeling electrical equipment with voltage ratings, equipment ratings, and other essential information to inform employees and contractors of potential hazards.

7. Incident Investigation and Reporting

In the event of an electrical incident or near-miss, NFPA 70E requires employers to conduct a thorough investigation to determine the root cause and implement corrective actions to prevent recurrence. This includes:

-

Immediate Response: Providing immediate medical attention to injured personnel and securing the area to prevent further incidents or injuries.

-

Investigation Team: Forming an investigation team comprising qualified personnel to investigate the incident, gather evidence, and interview witnesses.

-

Root Cause Analysis: Conducting a root cause analysis to identify underlying factors that contributed to the incident, such as equipment failure, human error, or inadequate safety procedures.

-

Corrective Actions: Developing and implementing corrective actions to address identified deficiencies, improve safety procedures, and prevent similar incidents in the future.

Importance of Compliance with NFPA 70E

While NFPA 70E itself is not a federal regulation, compliance with its requirements is crucial for promoting electrical safety in the workplace and reducing the risk of electrical injuries and fatalities. Key reasons why compliance with NFPA 70E is important include:

-

Worker Safety: Ensuring the safety and well-being of employees who work with or around electrical equipment, minimizing the risk of electrical shock, burns, arc flash incidents, and other hazards.

-

Legal and Regulatory Requirements: Demonstrating compliance with industry standards and best practices, which may be required by federal, state, or local regulations, as well as insurance providers or clients.

-

Risk Management: Identifying and mitigating electrical hazards through hazard assessments, safety procedures, training programs, and engineering controls to reduce the likelihood and severity of incidents.

-

Employee Confidence and Productivity: Promoting a safe work environment where employees feel confident in their ability to work safely around electrical hazards, leading to increased productivity and morale.

-

Business Reputation: Enhancing the organization's reputation as a safety-conscious employer that prioritizes employee health and safety, attracting and retaining skilled workforce.

Conclusion

NFPA 70E plays a critical role in promoting electrical safety in the workplace by providing guidelines and best practices for protecting workers from electrical hazards. By implementing NFPA 70E standards, employers can create a safer work environment, reduce the risk of electrical incidents, and ensure compliance with regulatory requirements. From hazard identification and risk assessment to safety procedures, training, and equipment maintenance, adherence to NFPA 70E helps organizations prioritize worker safety and mitigate the potential consequences of electrical accidents. By integrating electrical safety practices into daily operations and fostering a culture of safety, employers can effectively protect their most valuable asset—their employees—from the dangers associated with electrical work.