In the realm of environmental cleanup and spill control, the choice of sorbent material plays a critical role in effectiveness and efficiency. Sorbents are designed to contain and absorb liquids, primarily oil and chemical spills, preventing further contamination of soil and water bodies. Among various sorbent materials, meltblown polypropylene sorbents stand out as a superior choice over traditional granular sorbents due to their unique properties and benefits.

Introduction

Sorbents are essential tools in mitigating environmental damage caused by spills. They act swiftly to contain hazardous substances, thereby minimizing ecological impact and facilitating safe cleanup operations. While granular sorbents have been widely used for their absorbent properties, advancements in material science have introduced meltblown polypropylene sorbents as a more efficient alternative.

Understanding Sorbents

Sorbents are materials designed to absorb and encapsulate liquids upon contact, transforming hazardous spills into manageable solids. They are categorized based on their composition and structure, with each type offering distinct advantages in different spill scenarios.

Types of Sorbents

Granular Sorbents

Granular sorbents are typically composed of natural materials like clay or synthetic materials such as silica. They function by absorbing liquids into their porous structure, trapping them within the granules. This type of sorbent is effective for spills on solid surfaces and in scenarios where rapid containment is necessary.

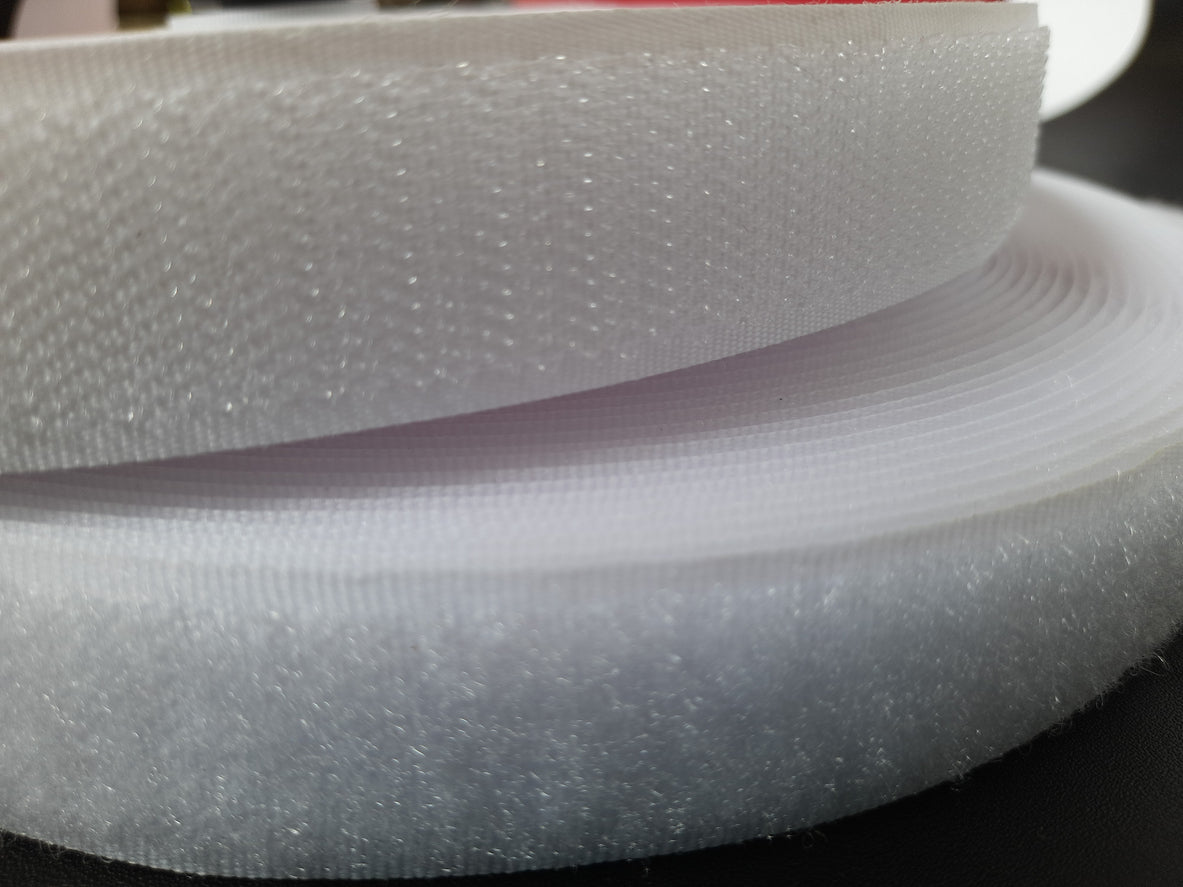

Meltblown Polypropylene Sorbents

In contrast, meltblown polypropylene sorbents are manufactured through a process that involves extruding polypropylene fibers into a fine mesh-like structure. This method creates a material with high surface area and porosity, enhancing its absorption capacity and efficiency in capturing liquids.

Comparison of Sorbents

Meltblown polypropylene sorbents offer several advantages over granular sorbents. They exhibit higher absorption efficiency, capable of rapidly containing and retaining liquids. This attribute makes them particularly effective in emergency spill response situations where quick action is crucial. Moreover, polypropylene sorbents are less prone to leaching absorbed liquids back into the environment, thereby reducing secondary contamination risks.

Applications of Meltblown Polypropylene Sorbents

The versatility of meltblown polypropylene sorbents extends across various industries and spill scenarios. They are extensively used in:

- Oil spill cleanup: Floating oil on water surfaces can be efficiently contained and absorbed using polypropylene sorbents.

- Industrial spill containment: In manufacturing facilities and industrial settings, these sorbents prevent hazardous chemicals from spreading and causing environmental harm.

- Environmental remediation: During environmental cleanup operations, polypropylene sorbents assist in restoring contaminated sites by safely containing and removing pollutants.

Advantages of Meltblown Polypropylene Sorbents

The key advantages of using meltblown polypropylene sorbents include:

- High absorption capacity: They can absorb several times their weight in liquids, ensuring efficient cleanup and containment.

- Rapid response capability: Polypropylene sorbents enable quick deployment and immediate action in spill situations, minimizing damage.

- Compatibility with various liquids: They are effective against a wide range of liquids, including oils, chemicals, and water-based substances.

Limitations and Considerations

While meltblown polypropylene sorbents offer significant advantages, their effectiveness may vary depending on the type of liquid and environmental conditions. It's essential to consider compatibility with specific chemicals and proper disposal methods to mitigate any potential environmental impact.

Case Studies and Examples

Numerous industries have adopted meltblown polypropylene sorbents for their reliability and performance in spill management. For instance, in the marine sector, these sorbents have been instrumental in containing oil spills and protecting sensitive marine ecosystems.

Future Trends in Sorbent Technology

The future of sorbent technology is increasingly focused on sustainability and biodegradability. Innovations in material science aim to develop sorbents that not only effectively manage spills but also minimize environmental footprint through biodegradable materials and recycling initiatives.

Conclusion

In conclusion, meltblown polypropylene sorbents represent a significant advancement in spill containment and cleanup technology. Their superior absorption capacity, rapid response capabilities, and compatibility with various liquids make them an ideal choice for industries and environmental agencies seeking efficient and sustainable spill management solutions.

FAQs

-

What are meltblown polypropylene sorbents made of? Meltblown polypropylene sorbents are composed of polypropylene fibers processed into a fine mesh structure.

-

How do meltblown polypropylene sorbents compare to granular sorbents in cost? While initial costs may vary, polypropylene sorbents are often more cost-effective due to their higher absorption capacity and reusability.

-

Are meltblown polypropylene sorbents biodegradable? No, polypropylene sorbents are not biodegradable. However, efforts are underway to develop environmentally friendly alternatives.

-

Can meltblown polypropylene sorbents be reused? Yes, depending on the level of contamination, polypropylene sorbents can be reused after proper cleaning and maintenance.

-

Where can meltblown polypropylene sorbents be purchased? They are available through environmental supply companies and specialized retailers catering to spill response products.